I Always wanted to have a longer stroke on the engine in the hope it would create more torque due to me always traveling two up with stupid amounts of luggage so I opted to base the tune around the H2 240 tune which was popular with the scooter racers before the invent of the TS1.

I chose the port timings I wanted to aim for from a two stroke tuning book by Graham Bell, I was aiming for between 130 – 135 degrees Transfer, 182 – 186 degrees Exhaust and 155 to 160 degrees Inlet. One thing that was annoying was having to use the complicated mathematical formulas to work out the port position I needed in the bore using a calculator so I decided to create an on-line calculator where I could just enter different port heights and it would give me the duration’s, you can find the calculators here

When I started playing with the on-line calculator I realised that the info given in the Webster Lambretta Tuning manual couldn’t be correct because the duration’s and port heights given didn’t correspond to each other. This made my mind up to just use the info given in the motorbike tuning manuals rather than any scooter related info that is widely taken as gospel in the scootering fraternity.

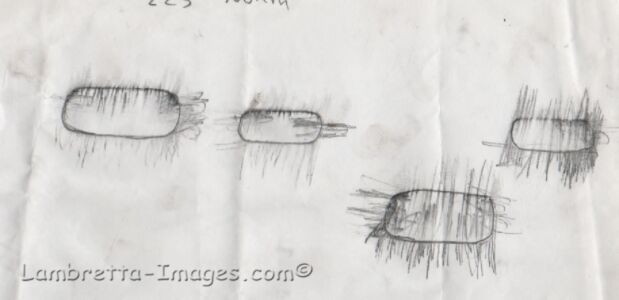

The first thing I did when I stripped the engine down was to make a trace of the barrel before I made any changes.

this is that trace:

The port timings were,:

Exhaust 172, Inlet 158, Transfers 117 .

Conservative considering how well it went!

I made the exhaust port 4mm wider, the inlet 5mm wider making them both 48mm wide, raised the exhaust to 34.5mm from the top of the barrel, left the transfers 47mm from the top and lowered the inlet so its bottom edge was 97mm from the top of the barrel.

The crank I decided to buy was a Tino 62 x 116 so together with these ports I would end up with 184 degrees exhaust, 132 degrees transfers and because i went a little wild shortening the inlet piston skirt I would have 170 degrees inlet timing. When I did the ports I decided to go for very oval shapes in the hope it would give a little reliability. An oval exhaust port eases the rings back into their groove to prevent snagging and an oval bottom edge to the inlet port reduces the pressure on the pistons inlet skirt which in turn reduces the risk of cracking occurring along the skirt.