Crank deflection load

This was a real surprise, just how little load is required to deflect a Lambretta crank shaft. I duplicated this test in 4 cranks and they were all the same. MEC, GT, Indian and PM. Please try it yourself.

I made two tests, one on the crank jig with a fixed load hung off the taper end and clocked with the load applied and unloaded (see pics below).

There is a case that the bearings provide support to crank so a deflection test was performed with an Indian crank, with new bearings, in a casing (the deflection was reduced but still reasonably linear).

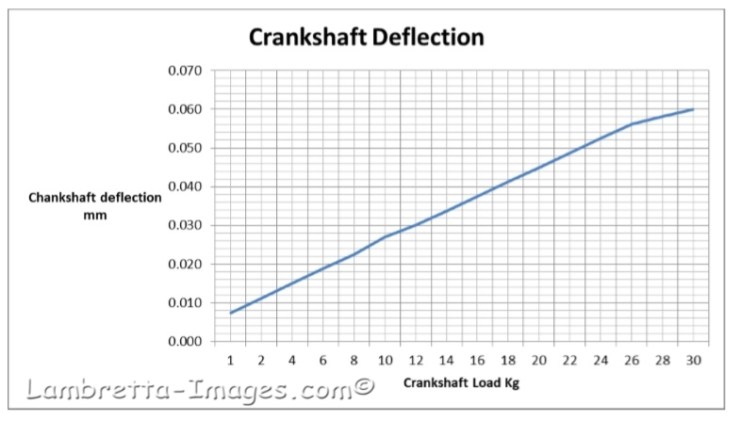

The load and deflection were measure on the threaded end of the taper but the readings were proportionally reduced by 25% to reflect the load and deflection occurring 20mm further inboard than the measurement point. This makes the loads and deflections representative and not exaggerated by leverage. You can see this by comparing the displacement of 0.01mm @ 1.8Kg in the graph below with the same load showing a deflection in the picture above of 0.025mm (The graph is using corrected values).

The key thing is that more load = more deflection. More deflection = more imbalance load (especially if you have a heavy flywheel).

Brilliant understanding of your knowledge is most valuable to anyone that rides and enjoys their scooters. Thank you for highlighting if this the case then bearings and cranks must get a longer life if treated with respect of other components to suit.